vineyard stone crusher with hydraulic adjustment BF702 S4 The BF702 S4 crusher bucket is suitable for excavators from 15 to 25 ton Despite its reduced size and weight make it grants high performance and its perfect for small/medium scale crushing work and urban sites For the 1in screen below the roll crusher the capacity has no correction factor and the area needed is 32/21 = 152 sq ft To handle the Crusher Efficiency Calculations Mineral Design of impact stone crus her machine T esfaye O T erefe, Getaw A Tefera Abstract: Crushers are one of the main equipment used for reducing size in (PDF) Design of Impact stone crusher machine

Crushing Plant Design and Layout Considerations 3 Table 2 Production Requirements – Typical Example: 60” x 89” primary crusher mill feed conveyor system Operating schedule calculation – for 3 x 8 hours per shift crusher design calculation pdf – Newest Crusher, 9/10 32K Reviews Case Impact Crushers Design And Calculations Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power So for these impact crusher parameter selection and calculation method of Impact Crushers Design And Calculations GitHub Pages Hydraulic crusHer The Rocklabs Hydraulic Crusher prepares trace metal samples prior to pulversing in a Rocklabs Ring Mill or similar piece of equipment It is designed to be easy to use, simple to maintain and costefficient to operate BENEFITS: • ACCURATE TRIMMING/ BREAKING The Hydraulic Crusher can trim and break rock samples or split Hydraulic crusHer Scott

13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The common primary Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impactCrushers an overview ScienceDirect Topics31 Vibration Level To investigate the vibration level of the screen unit (600 ton) and sand unit (600 ton) during normal operation, two measurement positions of the screen unit an d sand (PDF) Vibration Diagnosis of Sand Units in a Stone Crusher

Avoid trickle feeding the crusher Try not to trickle feed a cone crusher In addition to causing poor cone crusher productivity and product shape, trickle feeding has an impact on bearing alignment within said crusher A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to Hutchinson : Belt drive power transmission Hutchinson develops and manufactures complete power transmission system incorporating ribbed belts for HVAC, Conveying, industrial motors, agriculture and energy supply markets Stone Crusher Hutchinson Belt Drive Systems Case Impact Crushers Design And Calculations Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power So for these impact crusher parameter selection and calculation method of Impact Crushers Design And Calculations GitHub Pages

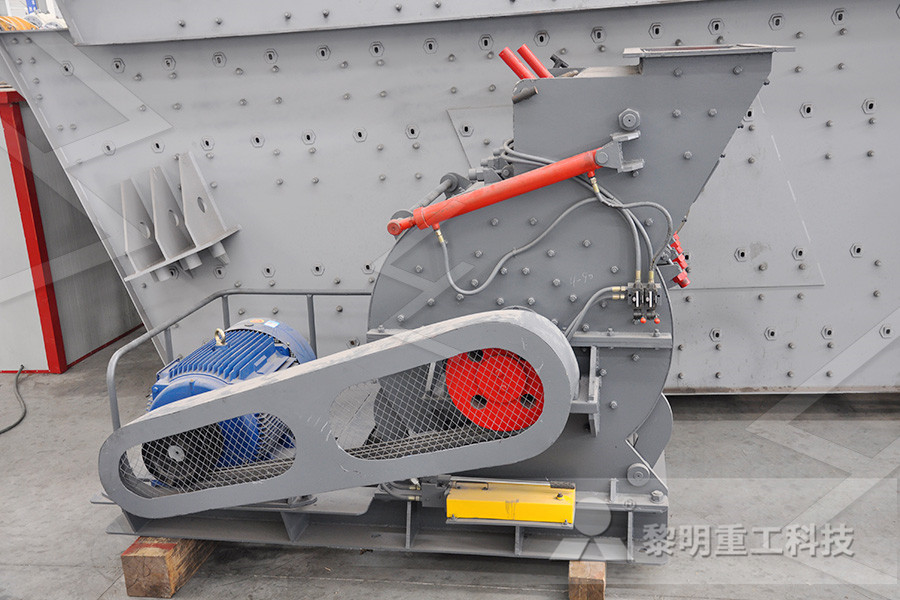

For impact crushers, a fully hydraulic crusher gap setting with automatic zeropoint calculation can speed daily setup Featured only on certain mobile impact crushers, a fully hydraulic adjustment capability of the crushing gap permits greater plant uptime, while improving quality of end product The capacities are based on the crusher receiving full, continuous feed of clean, dry, friable stone weighing 100 lb/cu ft These capacity tables show several significant differences between the two common types of primary Estimate Jaw Crusher Capacity Mineral Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impactCrushers an overview ScienceDirect Topics

Hydraulic Calculation Of Wet And Dry Risers Hoses And download free hydraulic calculation of wet and dry risers hoses and (gasliquid) system: heat transfer and hydraulicshydraulic manual although effective fire sprinkler systems are crucial to public safety, for years, the designers of Fire Sprinkler Systems Operating the crusher with a completely filled crushing chamber Choking Stoppage of the flow of material through the crusher, which is usually due to the wet and sticky material clogging exit points Circulating Load The amount of oversize material returned back to the crusher from a screen in a closed circuit crushing systemConstruction Working and Maintenance of Crushers for Gypsum is a very useful processed material Gypsum rock was formed in geological time through the evaporation Read MoreStone Crusher

mechanical crusher which would help to crush the used juice cans, paint cans and punched sheet metal waste This paper aims to design a crusher that could be installed anywhere and would aid crush of used wastes This paper involves the process of designing the crusher considering forces required for crushing and ergonomic Avoid trickle feeding the crusher Try not to trickle feed a cone crusher In addition to causing poor cone crusher productivity and product shape, trickle feeding has an impact on bearing alignment within said crusher A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to 12 tips to maximize cone crusher productivity Case Impact Crushers Design And Calculations Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power So for these impact crusher parameter selection and calculation method of Impact Crushers Design And Calculations GitHub Pages

The capacities are based on the crusher receiving full, continuous feed of clean, dry, friable stone weighing 100 lb/cu ft These capacity tables show several significant differences between the two common types of primary Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impactCrushers an overview ScienceDirect Topics Capacity of stone crusher jaw 20x12 Capacity of stone crusher jaw 20x12 Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Capacity of stone crusher jaw 20x12, quarry, aggregate, and different kinds of minerals capacity of jaw crusher plant

How To Calculate To Tph Of Any Crusher Plant How To Calculate Tph Of A Cone Crusher How can we calculate a tph of jaw crusher apr 25 2015 1000 tph crusher plant with vsi crusher jaw crusher and cone 18 jun 2013 crushing and screening plant for our formula to calculate tph of jawlearn more crusher efficiency calculationsit must be at least 36 in wide for an 18 x 36 jaw equipment evaluation of stone crusher [randpic] Crusher Efficiency Calculations A jaw crusher, like 2036 in the Jaw Crusher Table here above, would be able to take the maximum 12 in size quarry stone but it would not have the required 70 tph capacity needed Wholesale Trader of Stone Crusher Hydraulic Excavator by Established equipment evaluation of stone crusher Operating the crusher with a completely filled crushing chamber Choking Stoppage of the flow of material through the crusher, which is usually due to the wet and sticky material clogging exit points Circulating Load The amount of oversize material returned back to the crusher from a screen in a closed circuit crushing systemConstruction Working and Maintenance of Crushers for

mechanical crusher which would help to crush the used juice cans, paint cans and punched sheet metal waste This paper aims to design a crusher that could be installed anywhere and would aid crush of used wastes This paper involves the process of designing the crusher considering forces required for crushing and ergonomic 1 4 pieces of Angle arm two of 30 inch and two of 10 inch For the base, made up of cast iron 2 Cylinder or sleeve made up of steel 3 Piston made up of steel 4 Connecting rod made up of cast iron 5 Crank shaft up of cast ironHand Operated Can Crusher mechanical project Full report Gypsum is a very useful processed material Gypsum rock was formed in geological time through the evaporation Read MoreStone Crusher